How Automation Is Improving Manufacturing Processes

Automation is transforming manufacturing by integrating advanced technologies into processes. Companies leverage robotic systems to enhance efficiency and reduce labor costs. These systems also contribute to improved product quality through precise adjustments. Additionally, automated solutions facilitate better supply chain management, enabling more effective inventory tracking. As these advancements unfold, organizations must adapt to maintain competitiveness. The implications of these changes on the manufacturing landscape warrant further examination.

Enhanced Efficiency Through Robotics

Robotics has significantly transformed manufacturing processes, enhancing efficiency across various sectors.

The integration of robotic systems facilitates seamless workflow optimization, where machines and human operators engage in effective workforce collaboration. This synergy minimizes downtime and maximizes productivity, allowing for rapid adaptation to market demands.

Consequently, organizations leverage robotic integration not only to streamline operations but also to empower their workforce, fostering innovation and growth.

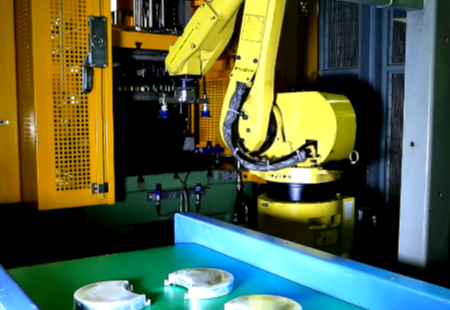

Cost Reduction With Automated Solutions

Implementing automated solutions in manufacturing environments leads to substantial cost reductions.

These systems facilitate significant labor savings by minimizing the need for manual intervention, thereby optimizing workforce allocation.

Additionally, operational flexibility enhances resource utilization, allowing companies to adapt swiftly to changing market demands.

Consequently, the integration of automation not only lowers expenses but also empowers organizations to maintain competitive advantages in a dynamic landscape.

Improved Product Quality and Consistency

As manufacturing processes increasingly incorporate automation, the resulting enhancements in product quality and consistency become evident.

Automated systems facilitate rigorous quality control through advanced sensors and data analytics, ensuring that standards are met consistently.

Additionally, consistency monitoring allows for real-time adjustments, minimizing variability.

This precision not only bolsters product reliability but also fosters consumer trust, ultimately driving competitive advantage in the market.

Streamlined Supply Chain Management

Efficiency in supply chain management is critical for modern manufacturing, particularly as automation technologies are integrated into operations.

Enhanced inventory tracking systems enable real-time data analysis, optimizing stock levels and reducing waste.

Additionally, advanced demand forecasting algorithms improve responsiveness to market fluctuations, ensuring that production aligns with consumer needs.

This synergy of automation fosters a more agile, efficient supply chain capable of meeting diverse demands.

Conclusion

In conclusion, automation is fundamentally transforming manufacturing processes, enhancing efficiency and reducing costs while ensuring product quality. Notably, a McKinsey report indicates that automation could increase global productivity by up to 1.4% annually, underscoring its potential to reshape competitive landscapes. As organizations adopt these advanced technologies, they not only streamline operations but also position themselves to respond adeptly to market demands, ultimately fostering sustainable growth in an increasingly dynamic industrial environment.